See also: Pre-Fab Modular Housing – a dozen articles and more

Includes a 10-minute video “Can Factory-Built Homes Help Solve The Housing Crisis?” link here

Additional links for the Garden Village apartments, here.

Can modular housing construction techniques help create quick and affording homes here in Arcata?

Part of a series of articles on innovative designs and construction techniques that might be used in Arcata. I am not suggesting that this design be copied — in my view, there is much here that is inappropriate for Arcata, and much that could be improved. It was built as student housing (very small bedrooms) and is far more dense (units per acre) than what is suitable for general housing. It also has zero parking, which I am opposed to. But in terms of innovation and solving a housing issue, it is noteworthy.

To skim through this article quickly: Just look at the photos and the text that’s in bold.

The Garden Village Apartments is a primarily student-occupied housing project built in 2016 in Berkeley. It is noted for its density (far more dense than we’d need here in Arcata), its extensive rooftop gardens (12,000 square feet, over 1/4 acre), and the modular units used in its construction. It is composed of 18 detached “towers” connected by walkways. This design provides every bedroom and living room with direct access to daylight and fresh air.

The Garden Village Apartments is a primarily student-occupied housing project built in 2016 in Berkeley. It is noted for its density (far more dense than we’d need here in Arcata), its extensive rooftop gardens (12,000 square feet, over 1/4 acre), and the modular units used in its construction. It is composed of 18 detached “towers” connected by walkways. This design provides every bedroom and living room with direct access to daylight and fresh air.

Here’s the density, as compared with Arcata’s Sorrel Place, the four-story low-income apartments on 7th Street, between I and J Streets:

Garden Village Apartments, Berkeley

Four stories and five stories, flat roof with with roof garden.

High density urban design. Zero parking spaces.

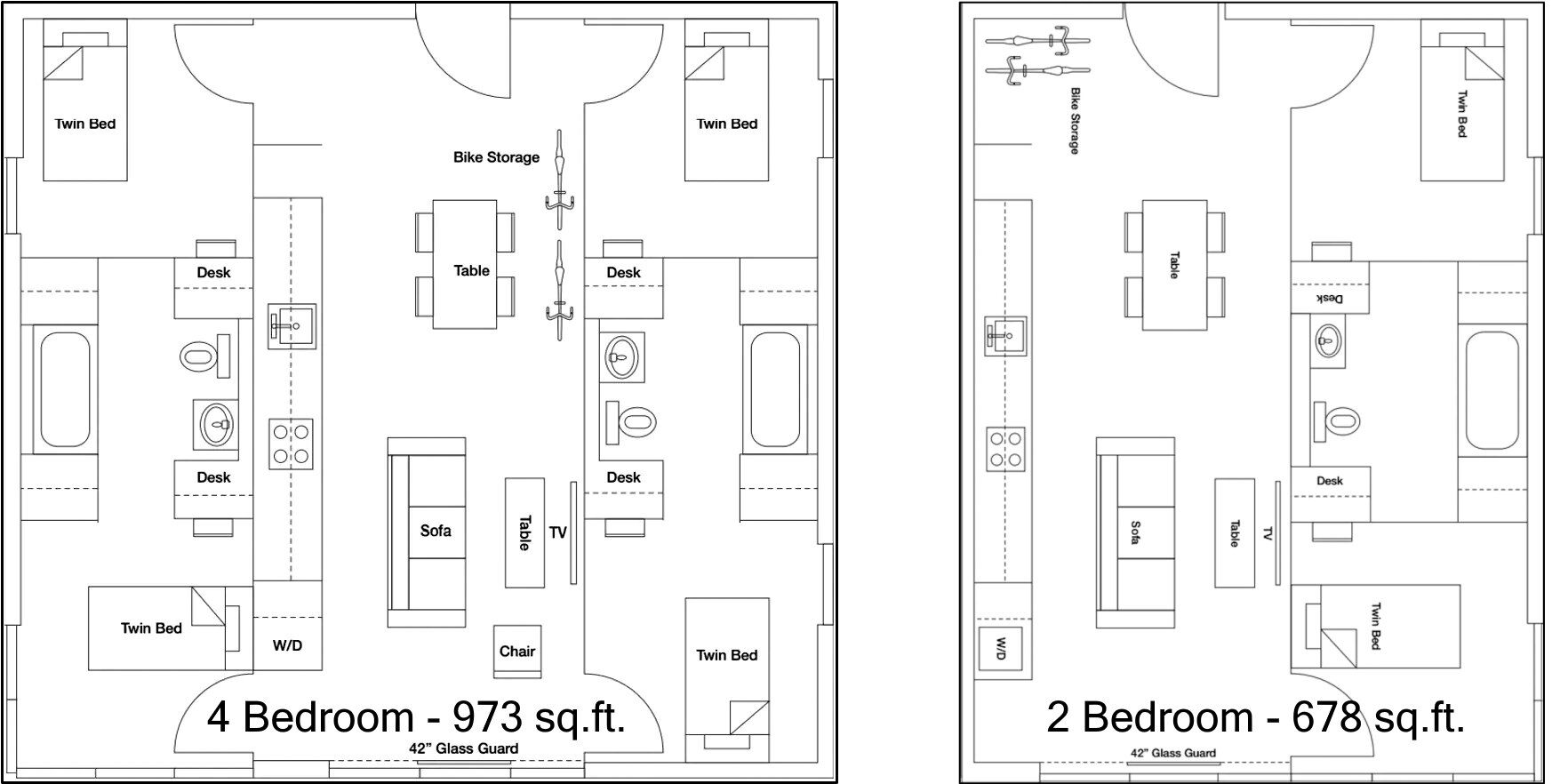

77 apartments. Two-bedrooms (678 sq.ft.) and four-bedrooms (973 sq.ft.)

Designed as Student housing with small bedrooms and small kitchens and living space. 236 beds total.

Lot size, 0.62 acres. Density: 124 units per acre, 381 bedrooms per acre (too dense).

Sorrel Place, Arcata

Four stories, flat roof.

15 parking spaces.

44 apartments of one-bedroom (609 sq.ft.), two-bedrooms (835 sq.ft.), and three-bedrooms (1,110 sq.ft.).

Designed for adult and family living. 83 beds total.

Lot size, 0.69 acres. Density: 64 units per acre, 120 bedrooms per acre.

In the December 12, 2022, OLLI Affordable Housing presentation (link here), Danco President Chris Dart was asked about modular construction. In many instances, modular construction has resulted in a 20% reduction in the cost of actual construction. But — and this is a big “but” — there are many other costs involved in developing a property, other than the actual construction costs. And a definite limiting factor for us here on the North Coast is the cost of transportation for the modules.

The word “modular” is used in different ways, so let’s clarify. In the order of complexity:

- There is modular housing that consists of factory-made units for single-story detached housing — typically with units eight feet wide and homes made of 1, 2, or 3 widths. The units have a roof in place and are generally “stick-built,” framed with wood. This method of construction results in lower-cost single-family homes.

- Modular components for one-of-a-kind or small quantities of one- or two-story single-family homes. In cases of limited road access to the site, the modules can be airlifted via helicopter. Good for quick turn-around from site prep to move-in. Can be cost-effective in some circumstances, but lacking economies of scale of large factory production.

- Identical modular stacking units. Often the modular units are identical, but not necessarily. See the Santa Maria project and others in this article. Often (but not necessarily) designed as long, narrow modules consisting of two ~350 sq.ft. studio apartments at each end and a hallway in the middle. The resulting apartments have windows only at one narrow end — not ideal from a quality of life perspective.

- Two or more types of modular components that “snap together” (not literally) to create a variety of apartment sizes and types, as in the Berkeley Garden Village apartment s. This design has maximum flexibility and can be useful in smaller buildings, where each apartment has windows on corners and more than one wall. To me, this form of modular design and construction is ideal.

- A variety of combinations. The ground floor may be constructed on site of concrete/steel, and then modules stacked on top.

Some modules have the exterior cladding in place from the factory, and other designs have the exterior cladding put up on-site, after the modules are stacked. Some modules include all furniture and appliances for instant move-in — ideal for dorms or assisted supportive/transitional housing.

Modular housing could be an answer to the State housing crisis

The “Tahanan” permanent supportive housing complex in San Francisco had costs of $385,000 per unit and from announcement to occupancy was done in 3 years. More typical in San Francisco is a cost of $600,000 per small studio unit, and a time-frame of 5 to 7 or even 10 years.

According to the module factory promotions, modules can be assembled into apartment buildings 40% more quickly and 20% cheaper than traditional construction.

From the website of Factory OS in Vallejo, California:

20% – 40% less expensive

40% – 50% faster

500+ locals trained & employed

We’re not just building homes.

We are manufacturing the future.

The original Arcata1.com article includes modular units from factories in Vallejo, Sacramento, Klamath Falls OR, Idaho, Canada, and China.

Garden Village Apartments in Berkeley, California

Berkeley sprouts creative housing, topped by a working farm

by John King published in the San Francisco Chronicle

December 24, 2016

https://www.sfchronicle.com/bayarea/article/Berkeley-sprouts-creative-housing-topped-by-a-10816953.php

The unexpected twist in the new housing complex on Berkeley’s south side isn’t just the rooftop farm. It’s that the fields of edible greens rest above 18 freestanding structures, vertical pods, that hold 77 apartments in all.

Put those two elements in the middle of a fairly dense city, and they combine to make a point that’s easy to forget: Our society’s need for pedestrian-friendly housing doesn’t need to be satisfied in cookie-cutter ways.

This welcome fact runs counter to what we see in growing cities across the Bay Area, the state, even the nation as a whole — anywhere new housing is packaged in squat, costumed boxes along busy streets. The planning theory is great. The execution too often is generic at best.

Not so at the corner of Dwight Way and Fulton Street on the edge of downtown Berkeley, where the boxy collage of Garden Village is like nothing that you’ve seen.

On the roof of RAD Urban’s Green Village in Berkeley, CA

On the roof of RAD Urban’s Green Village in Berkeley, CA

The design is by Stanley Saitowitz, one of the region’s few architects whose work is always interesting — even his less-successful buildings don’t feel formulaic, because there’s an underlying concept that’s tied to aesthetics and the setting. In this case, the blocks south of UC Berkeley, where students inhabit everything from chopped-up single-family homes to small apartment buildings and high-rise dorms.

“Berkeley is a place of detached buildings,” said Saitowitz, who lives and works in San Francisco but taught at Cal’s College of Environmental Design for more than 30 years. “I wanted to explore how to add density within that tradition.”

Construction methods also shaped the design. Developer Nautilus Group, which also served as architect of record, wanted to use prefabricated components throughout the complex. That way, portions of the apartments could be manufactured elsewhere, then assembled on-site.

Saitowitz and his firm, Natoma Architects, responded with a system of two large modules — one containing two small individual bedrooms and a shared bathroom, the other holding the living, dining and kitchen areas. Snap two together, and you’ve got a two-bedroom apartment. Put bedroom modules on either side of the communal section, and it’s a four-bedroom suite.

That ingenuity helped Saitowitz get the job. The next step, how to deploy the modules, is what makes you stop and look twice.

The “village” consists of 18 buildings of three to five stories, with each floor holding a separate apartment. The pod-like stacks are connected by steel bridges with open grillage below your feet. Where the bridges serve as walkways — outdoor corridors — the square buildings are 5 feet apart. Where there’s a ground-level landscape and fresh air up above, the width is as much as 15 feet, with protruding window frames to add a bit of privacy.

The specific numbers are less important than the overall impression — a grid brought to life in 3-D.

From the street the look can be forbidding, though Saitowitz clads every other pod in a dark red cement board. He calls it “my homage to Berkeley brown-shingle homes,” which also adds a contrast to the white pods in between. But the open-air corridors and multistory sight lines make the interior of the grid surprisingly cozy, with a collegial feel that’s much more inviting than your standard apartment block.

This is no mean feat given that the 77 apartments together contain 236 beds. And the word “collegial” is appropriate, because UC Berkeley signed a master lease with the developer and operates it as part of the student housing system.

Cozy turns captivating as you ascend.

Follow the bridges from one level to the next and it’s as if you’re inside a honeycomb. The higher you get, the more there is to see and do.

Two of the interior pods stop at three levels and are topped by communal terraces that get use throughout the day when studies and weather allow. One more level up, you encounter the startling contrast of panoramic views — and a dissected farm where you can touch the ground or snip off a sprig of parsley.

This time of year, between harvests, some pods show nothing but dirt. Others are softened by abundant mounds of green parsley and purple kale. One roof is dotted with red radishes waiting to be picked.

https://www.gardenvillageapt.com/

Garden Village is an award-winning 77-unit, furnished student housing and co-living complex located at 2201 Dwight Way. Built in 2016, the complex consists of 18 free-standing buildings connected by open-air walkways providing abundant natural light both inside and out. A fully operational commercial farm operates on the rooftop complex and is open to residents to visit, hang-out, or get involved. Stunning views across the bay are enjoyed from many vantage points. Outdoor and indoor spaces encourage community. Our units include both 2-bedroom and 4-bedroom configurations, with 1 bathroom per two bedrooms shared “jack-and-jill style”. Every bedroom has 9-foot ceilings and floor-to-ceiling windows allowing natural light. The units are fully stocked with all of the furniture and appliances that our residents may need. Interior finishes include wood cabinets, quartz countertops and backsplash, faux-wood plank vinyl flooring, combination tub/shower with quartz surround, porcelain pedestal sinks, both natural and efficient LED lighting.

Additional links

https://www.aia.org/showcases/155456-garden-village

https://www.gardenvillageapt.com/

RAD Urban Is Trying to Change the Industry, Piece by Piece

The modular revolution promises to shake up Bay Area housing February 16, 2018

Top Leaf Farms, urban portfolio here. Top Leaf Farms developed and were the initial operators of the 1/3 acre rooftop farm on the rooftop of the Garden Village Apartments. The rooftop garden is now operated by Bluma Flower Farm as a flower garden.

RAD Urban completed a 43-unit modular apartment building at 4801 Shattuck Ave. in Oakland.